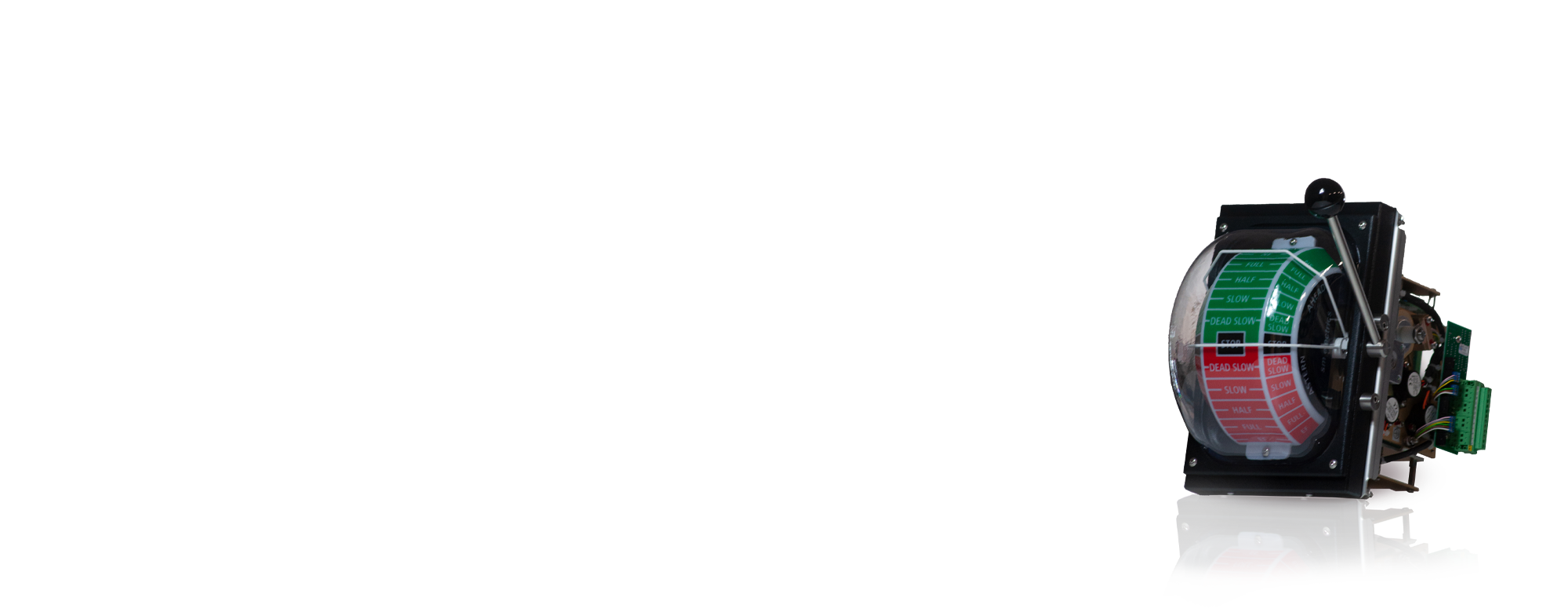

Engine Order Telegraph EOT

sm electrics‘ Engine Order Telegraph (EOT) formerly designed and distributed by Stein Sohn respectively Interschalt represent the embodiment of safe and sustained μP controlled human machine interface as a basic part of the connected remote propulsion system.

Type approved by major classification societies the equipment is available for various control application. The highly integrated system is administrating a single interface to the potential propulsion system by high-precision shock resistant potentiometer, contact-free optical current transmitter or other defined physical interface unit. The well established μP controlled “Electrical Shaft” allows a secure Bridge FWD EOT’s remote control by corresponding lever controller located typically on the Bridge Wings and/or Bridge AFT.

Type approved by major classification societies the equipment is available for various control application. The highly integrated system is administrating a single interface to the potential propulsion system by high-precision shock resistant potentiometer, contact-free optical current transmitter or other defined physical interface unit. The well established μP controlled “Electrical Shaft” allows a secure Bridge FWD EOT’s remote control by corresponding lever controller located typically on the Bridge Wings and/or Bridge AFT.

The main purpose of sm electrics‘ Engine Order Telegraph system is to generate the desired RPM or pitch value for the connected propulsion remote control system by a sustained and reliable lever – known as well as human machine interface (HMI).

In case the connected propulsion remote control system is disturbed the engine order telegraph system is in use to transfer manoeuvre commands to the engine control room or, if required, directly to the engine room‘s ME local station. The given manoevre command activates an audible alarm as long as the command has been accepted by corresponding operation at the connected participants.

The modular system structure allows to extend the system by wing control units. All telegraphs located on the bridge e.g. bridge FWD, bridge AFT, wing SB, wing PS are connected to each other by a virtual mechanical shaft to make them work synchronously. That virtual shaft is called Electrical Shaft and oprerates as a remote control of the main bridge FWD telegraph which is providing the main interface to the connected propulsion remote control system.

The centralized A067 mt-Bus controller, mostly located inside the engine control room console, controls and monitors all network participants and provides further interface signals for ER call, VDR and connected IAMC systems.

Download:

Brochure

In case the connected propulsion remote control system is disturbed the engine order telegraph system is in use to transfer manoeuvre commands to the engine control room or, if required, directly to the engine room‘s ME local station. The given manoevre command activates an audible alarm as long as the command has been accepted by corresponding operation at the connected participants.

The modular system structure allows to extend the system by wing control units. All telegraphs located on the bridge e.g. bridge FWD, bridge AFT, wing SB, wing PS are connected to each other by a virtual mechanical shaft to make them work synchronously. That virtual shaft is called Electrical Shaft and oprerates as a remote control of the main bridge FWD telegraph which is providing the main interface to the connected propulsion remote control system.

The centralized A067 mt-Bus controller, mostly located inside the engine control room console, controls and monitors all network participants and provides further interface signals for ER call, VDR and connected IAMC systems.

Download:

Brochure

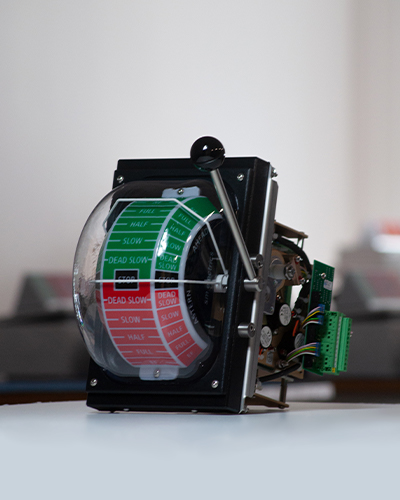

Retrofit Story - Engine Order Telegraph EOT

Last week we successfully replaced an entire Engine Order Telegraph system, which was already 20 years old and started to show some sporadic failures. As the Engine Order Telegraph is the human

Machine interface between the Captain and the main engine, it has to work properly at any time. Therefore we suggest our customer to consider a full replacement in case the system has already exceeded a certain age. At first sight it seems like an exaggeration, but here are the key advantages:

• Replacement can be planned wisely in terms of location and time slot.

• The money invested will go into equipment and not into travel expenses and working hours, which can be high depending on the location.

• System failure probability will be reduced massively for future operation.

• The replacement can be done within 6-10 hours during a port stay

• One year of warranty for the whole system

• 10 years of guaranteed spare part availability

Based on our experience, the costs for two service attendances on board can already exceed the price of the whole system replacement. It is also important to remember, that after a partial replacement of the faulty equipment, the failure probability is only reduced for the renewed part.

Machine interface between the Captain and the main engine, it has to work properly at any time. Therefore we suggest our customer to consider a full replacement in case the system has already exceeded a certain age. At first sight it seems like an exaggeration, but here are the key advantages:

• Replacement can be planned wisely in terms of location and time slot.

• The money invested will go into equipment and not into travel expenses and working hours, which can be high depending on the location.

• System failure probability will be reduced massively for future operation.

• The replacement can be done within 6-10 hours during a port stay

• One year of warranty for the whole system

• 10 years of guaranteed spare part availability

Based on our experience, the costs for two service attendances on board can already exceed the price of the whole system replacement. It is also important to remember, that after a partial replacement of the faulty equipment, the failure probability is only reduced for the renewed part.

Ask us for an individual retrofit offer: Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein.